As winter brings its icy touch, lash technicians and enthusiasts alike may notice changes in the performance of lash extension glue. Understanding the impact of colder temperatures on adhesive properties is crucial for maintaining optimal lash retention and ensuring client satisfaction. In this article, we’ll explore how winter affects lash glue and share tips on how to navigate the challenges.

How winter affects lash glue: Changes in Temperature and Humidity

Winter often brings lower temperatures and decreased humidity levels. Both factors can significantly influence the lash extension glue‘s curing process.

Cyanoacrylate is the component responsible for the distinctive drying characteristics of lash glue. It facilitates the rapid drying of the adhesive, ensuring the lashes stay securely in position for a few weeks. For optimal performance, cyanoacrylate-based lash glue generally needs a humidity level of 45-55% and a temperature range of 18-22 degrees Celsius or 64.4-71.6 degrees Fahrenheit. Deviations from these optimal conditions can lead to slower bonding or poor adhesion.

Temperature

The viscosity of lash adhesive, being a liquid, is influenced by temperature. Lower temperatures cause the adhesive to solidify, resulting in a lower viscosity (harder consistency) and a longer drying time. Conversely, higher temperatures cause the adhesive to liquefy, leading to a higher viscosity and faster drying.

These temperature fluctuations can catch you off guard during application. To ensure consistent and optimal results, it’s recommended to maintain the room temperature between 18-22°C (64.4-71.6°F). Rapid temperature changes may cause condensation inside the adhesive bottle, significantly reducing its lifespan.

Improper storage, particularly exposure to condensation, poses a significant threat. Water droplets entering the bottle can initiate the curing process, rendering the glue unusable. This situation is akin to items taken out of the fridge, where condensation forms both inside and outside the container.

A simple precaution to prevent this is to take the adhesive home each night. This can ensure consistent control over the glue’s environment. This control includes regulating both humidity and temperature. Fluctuations in humidity and temperature can lead to problems like lash glue drying too quickly or not adhering properly. By actively managing these factors, the risk of such issues occurring is minimized. Though it may seem like a minor effort, it can significantly enhance the performance of lash glue in the winter.

>> Eyelash Glue Dried Up In Bottle? We’ll Show You How To Handle!

Humidity Fluctuations

In winter, humidity decreases as cold air has a lower capacity to hold moisture compared to warm air. In low humidity conditions, lash extension glue may not dry properly. If the room humidity is below the optimal level (less than 60%), the cyanoacrylate in the glue lacks sufficient water vapor for proper curing. Cyanoacrylate requires moisture to initiate the drying process, and without enough moisture, the glue remains wet and fails to transform into a solid, adhesive substance that securely bonds lash extensions to natural lashes.

This situation can lead to various issues, such as ‘lash stickies,‘ poor placement, and increased exposure to cyanoacrylate, potentially triggering allergic reactions to the glue. Lash stickies occur when adjacent lash extensions adhere to each other, even if proper isolation was initially performed. If the glue takes too long to dry, it can clump the surrounding lashes, causing stickiness and the risk of permanent loss of natural lashes.

Additionally, low humidity can result in extension lashes not adhering properly, causing them to lean or slip upon placement. The lack of instant, magnetic attachment may lead to frustration for the technician.

Furthermore, extended exposure to uncured glue increases the risk of clients developing a glue allergy. The longer the cyanoacrylate fumes are present, the higher the likelihood of adverse reactions in clients exposed to the glue for an extended period of time.

Lastly, in addition to lowering overall humidity in winter, indoor heating systems can further reduce moisture levels. Adequate humidity is crucial for the glue to polymerize and create a strong bond. Technicians should invest in a reliable hygrometer to monitor humidity levels and consider using a humidifier to maintain an optimal environment.

Changes in your clients’ skin

Before we explore what could affect your workspace, let’s talk about how changes in your clients’ skin might impact our adhesive’s performance.

It might seem strange at first—how does your clients’ skin condition affect our glue? During the winter, people’s skin tends to get drier. This dryness can affect our eyelash glue in two ways:

- Slower Drying Time: Less moisture can make the glue take longer to dry. This may lead to more fumes and a risk of lash extensions leaning since the bond hasn’t fully dried. This could mess up the overall look of the lashes, causing frustration for both you and the client.

- Too Much Moisturizing: Clients might use extra moisturizer to combat dry skin. Ironically, this can make the skin and lashes too oily, making it tough to keep the lashes in place. Dealing with oily lashes can be a real headache.

Being aware of how changes in your clients’ skin can affect the glue will help make the lash application process more successful and satisfying.

What to do to reduce the impact of temperature and humidity on lash adhesive

1. Invest in Dehumidifying Appliances

Ensure the right humidity for your lash adhesive by referring to the recommended conditions on the adhesive bottle. Maintain a humidity range of 45-55% in your lash room, using a warm mist humidifier or dehumidifier as needed. Invest in a hygrometer to monitor humidity levels, and consider using a silica packet to absorb excess moisture. While these tools may seem costly, they are essential for preventing retention issues that could impact your lash business.

2. Adjusting Application Techniques

Winter conditions require lash technicians to understand how winter affects lash glue and ways to adjust their application techniques. Working more swiftly and efficiently can help compensate for the slower curing time. Additionally, using slightly more adhesive than usual may be necessary to ensure a secure bond between the natural lash and the extension.

3. Use a Nanomister

Nano mist sprays emit an ultra-fine mist of water particles. This fine mist is advantageous because it covers a larger surface area without drenching the lashes or the surrounding areas. The mist also provides a controlled amount of hydration to the lashes, preventing them from drying out too quickly during the application of lash extensions.

In environments with low humidity, the drying time of lash glue in the winter can be prolonged. The nano mist spray helps counteract this by introducing moisture to the air. Similarly, in regions where the air is exceptionally dry, the nano mist spray becomes a valuable tool to maintain an optimal level of moisture during the lash extension process.

4. Transportation

Lash extension glue can be sensitive to extreme temperatures, even during transportation. In winter, the back of a delivery van may be colder than your refrigerator, so ensure the glue warms up to your treatment room’s temperature before opening it for the first time. Technicians should also take precautions to keep their adhesive at a consistent temperature when traveling to and from appointments.

5. Storage

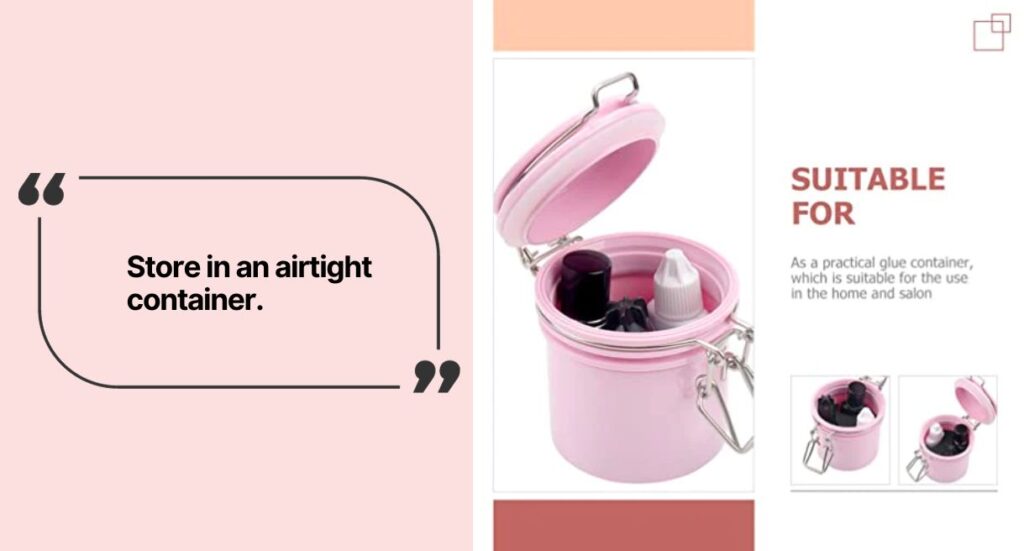

Keep lash glue in a dark, airtight container away from other products in a cool, dry place. Use a silica packet to absorb moisture. Even when not actively applying lashes, maintain the proper room temperature and humidity. Storing glue in a temperature-controlled environment is essential to maintaining its effectiveness.

6. Educating Clients

Winter weather doesn’t only impact the application process but can also affect the longevity of lash extensions. Educating clients on proper aftercare during the colder months is crucial. Advise clients to avoid exposing their lashes to extreme cold, as well as sudden temperature changes, to prevent premature lash extension loss.

Conclusion

As winter settles in, lash technicians must be proactive in addressing the challenges posed by colder temperatures. By understanding how winter affects lash glue and implementing the appropriate adjustments, professionals can ensure high-quality results and satisfied clients throughout the chilly season.

Visit https://vietnamlash.com/