Introduction

Understanding the lash manufacturing process is essential to choosing quality and safe products.

Read the article below to understand the steps in the lash manufacturing process, from raw materials to packaging, and discover the supplier selection criteria we share so you can make the choice best for your business.

Steps in the lash manufacturing process

Select eyelash material

This step is choosing the best materials to ensure the lashes are soft, safe and comfortable to wear.

Popular materials:

- Synthetic fibres: Known for their durability and affordable price, synthetic eyelashes are a suitable choice for customer segments that do not require too much quality but still want impressive eyelashes.

- Silk lashes: Lightweight and soft, these are ideal for clients seeking a more natural appearance.

- Artificial mink fur: Mimicking the texture of real mink, this material offers premium softness without the ethical concerns of using animal fur.

- Korean PBT fibres: Famous for their durability, elasticity and ability to retain their shape even in wet conditions. PBT (Polybutylene Terephthalate) is a popular choice for high-quality lashes, providing softness and flexibility that is ideal for wear.

Material selection criteria:

- Softness: Ensures comfort for the wearer.

- Safe for skin: Minimizes irritation for customers with sensitive skin

- Safety: Eyelashes need to comply with international standards (for example: ISO, SGS).

Shaping and processing eyelashes

After selecting materials, the lashes undergo shaping and processing to achieve their signature look.

Manual process vs Automation:

- Manual process: This method requires technicians to shape each individual lash, providing high precision when customizing intricate details such as curl pattern, length, and thickness.

This is a method that requires specific ingenuity to suit the needs of each customer. This process offers great flexibility and personalization compared to automated approaches.

- Automation: In contrast, automation uses machinery to speed up production, ensuring consistency and efficiency, especially for large orders.

This method mass produces products with uniform shape, curvature and color, so it is suitable for large production orders that do not require too much customization.

Deciding factors:

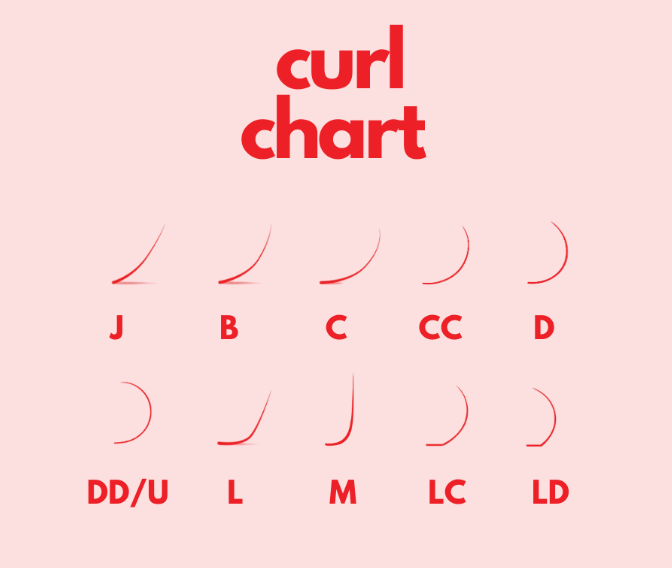

- Curvature: Affects the lash’s ability to blend naturally with real lashes.Includes 3 popular types of curves: Mild curl (J-Curl), Medium curl (B-Curl, C-Curl), Strong curl (D-Curl, L-Curl)

- Length and thickness: Depending on market trends and customer preferences, the length and thickness of eyelash extensions can change flexibly.

Thickness can be customized from 0.03 mm to 0.05 mm for a natural look or from 0.07 mm and thicker for increased density.

- Color: There are many options with many different colors (black, brown, blue, purple, etc.)

This step is a step that determines the curl of the eyelashes (like C or D), length, thickness and even color.

Check product quality

Stringent quality checks ensure the lash manufacturing process meets high standards before reaching customers.

Inspection process:

- Prevents breakage during application.

- Ensures consistent color and curl retention.

- They are safe and gentle on the skin.

Compliance with International Standards: Products need to comply with ISO and SGS quality certifications, ensuring safety and effectiveness when used.

Packaging and finishing products

Packaging plays a vital role in branding and customer satisfaction.

Customisation options:

- Packaging design including logo and specific packaging style is closely associated with brand identity.

- Attach instructions for use, care or promotional materials.

- Choosing the right packaging will keep your lashes safe throughout transportation and use.

Important criteria when choosing a lash manufacturing

High-quality products

The quality of the eyelashes is the most important factor. Therefore, look for manufacturers:

- Use safe, skin-friendly materials.

- Lashes that are durable, lightweight, and easy to apply.

- Follow international quality standards like ISO or SGS certifications.

Supply stability

Manufacturers need to ensure a stable supply so you don’t have to worry about being out of stock, especially during peak times. Make sure they can:

- Handle large orders without delays.

- Maintain consistent quality in every batch.

Customized options

If you want lashes tailored to your brand or specific customer needs, choose a manufacturer that offers customization, such as:

- Different lash styles, lengths, and curls.

- Personalised packaging with your logo and design.

- Special features like colored lashes or mixed sets.

Competitive Pricing

For salon owners and wholesalers, price is very important. You need to find suppliers:

- Offer discounts on bulk orders.

- Price goes hand in hand with the quality of goods.

- Offers clear pricing, no hidden fees.

- Discount when purchasing cross-selling products.

By keeping these points in mind, you will find the right manufacturer for your business needs and deliver perfect products to your customers.

Common challenges when buying lashes from manufacturers

When it comes to eyelash production, there are some common challenges that salon owners and wholesalers may encounter when purchasing. Here are some of them and how to solve them:

Lack of information about the lash manufacturing process

It’s important to know exactly how your lashes are made. Sometimes, manufacturers don’t provide enough details about the lash manufacturing process.

Solution:

- Request documents and videos illustrating each step in the lash manufacturing process, from raw materials to finished products.

- Directly visit the production process at the factory (if possible).

- Required to provide safety and quality certificates meeting international standards (for example ISO, SGS).

Substandard raw material quality

Manufacturers use poor-quality materials that can cause eyelashes to break easily or cause skin irritation when used by your customers.

Solution:

- Only cooperate with reputable suppliers and perform regular quality checks.

- Prioritize skin-friendly materials, such as Korean PBT fibre or artificial mink hair.

- Develop a clear set of quality standards to apply in all stages of importing goods.

Limited customization options

Some manufacturers don’t offer much flexibility when it comes to customizing lashes to your needs.

Solution:

- Look for manufacturers that offer a variety of customization options. Can include eyelash style, length, curl, etc. and even individual packaging design.

- Request a sample before placing a bulk order to test the supplier’s ability to meet custom requirements.

Uncompetitive prices for wholesalers

Wholesalers may find that some manufacturers offer prices that are too high, making it hard to stay competitive.

Solution:

- Negotiate for better pricing, especially on bulk orders. Refer to the article: 5 negotiating tips for better deals when buying bulk individual lashes.

- Cooperate with manufacturers that have good incentive policies, ensuring competitive prices while maintaining quality.

- Consider the value of the lashes—sometimes, spending a little more on higher-quality products can benefit your business in the long run.

By understanding these challenges and knowing how to address them, you can choose a manufacturer that meets your needs and helps your business succeed.

VietnamLash – Leading lash manufacturing

At VietnamLash, quality is at the core of everything we do. We strictly comply with and are certified by international quality standards. Our eyelashes are mostly made of high-quality materials such as Korean PBT fibres and artificial mink fur, famous for their soft and skin-friendly properties.

In fact, 95% of our customers report being very satisfied with the quality of the lashes we supply, with many finding them comfortable to wear and durable even in harsh conditions humid.

Furthermore, we offer a variety of customization options to suit B2B clients looking to build their brand. From lash style, length and curl to packaging design, we work closely with customers to deliver exactly what they need.

“One of our customers, an owner salon based in the US, reported a 40% increase in customer retention after switching to our custom eyelash extensions, thanks to the Suitable shape and attractive packaging”

Conclusion

The above article answers questions about how eyelash extensions are created. Choosing the right lash manufacturing partner requires you to carefully consider many factors such as quality, durability, safety, price, etc. Hopefully, this article will help you. Look deeper and be able to make the right choice when choosing a supplier to cooperate with.

If you are a salon, spa owner or wholesaler, contact VietnamLash today to receive professional advice, and competitive quotes and receive high-quality eyelash extension products that suit your business needs!

+84 862 765 053

+84 862 765 053